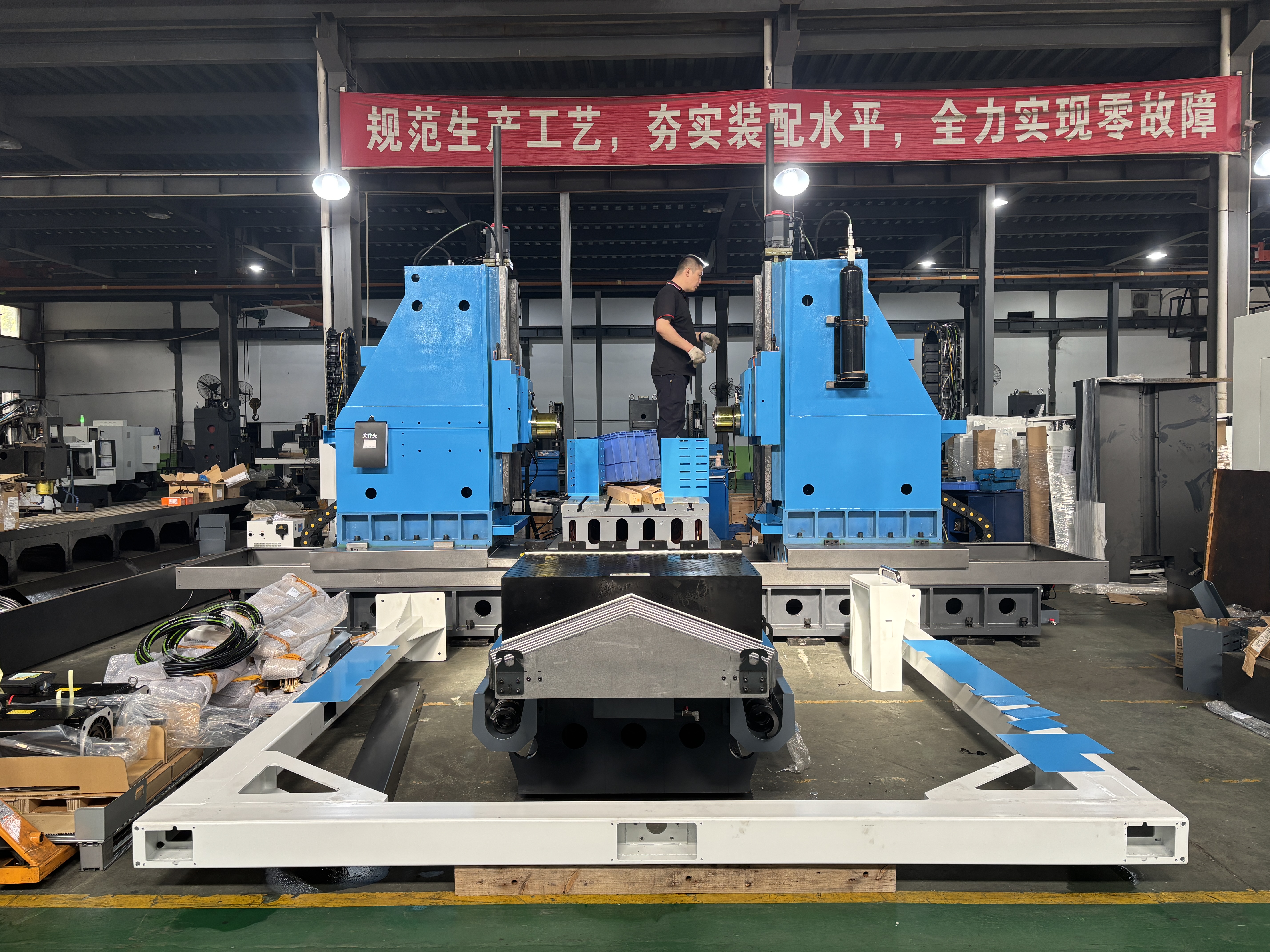

JOINT Double - sided Boring and Milling Machining Center: Redefining Precision and Efficiency in Machining

September 25,2025

In the realm of machining, achieving high precision and efficiency simultaneously has always been a pursuit. The JOINT Double - sided Boring and Milling Machining Center series emerges as a game - changer, revolutionizing how large box parts are processed.

Unveiling Outstanding Features

The foundation of this machining center is built on a gantry base structure. This design choice is not arbitrary; it significantly enhances rigidity and precision retention, ensuring that the machine maintains its accuracy over extended periods of use. When it comes to the columns, the double columns on the side adopt an inverted ladder horizontal structure. For the axes, the X and Z axes utilize roller guides, while the Y axis employs a hard rail. This combination, along with precision shoveling, guarantees the rigidity and high precision of horizontal boring and horizontal milling operations.

Adjusting the concentricity of spindles on both sides is a breeze, thanks to the column and saddle adjustment structure. This not only saves time but also ensures the long-term precision retention of the equipment, a crucial factor for consistent machining quality.

One of the most remarkable aspects is its simultaneous double - sided processing capability. It can carry out boring and milling operations at the same time, and with two spindles processing separately, the overall processing efficiency gets a substantial boost.

Powering the operations is a dual - channel CNC system. This advanced system controls 6 axes, assisting users in process and fixture design, as well as parameter optimization. It provides efficient processing solutions, making complex machining tasks more manageable.

High - Precision and Efficient Processing at Its Best

This series of boring and milling machining centers stands out with its ability to perform simultaneous milling and boring on both sides. By eliminating the need for secondary clamping of workpieces, it not only greatly improves processing efficiency but also reduces the error associated with secondary clamping, thereby enhancing processing accuracy on both sides.

It finds extensive use in processing large box parts, such as connectors of engineering machinery. Moreover, the stroke of the machine can be customized according to users' processing needs, ensuring that it can adapt to a wide range of machining requirements.

Powering Diverse Industries

The application of the JOINT Double - sided Boring and Milling Machining Center spans across various industries. In the construction sector, it plays a vital role in manufacturing components for cranes and other lifting equipment, ensuring their structural integrity and precision. For engineering machinery, it is indispensable in producing parts that require high accuracy and durability, contributing to the overall performance and reliability of the machinery.